Rotary kilns, like any other high-performing piece of equipment, need regular inspection and maintenance to ensure ideal operation. The list below highlights the areas of a kiln that should consistently be inspected:

-

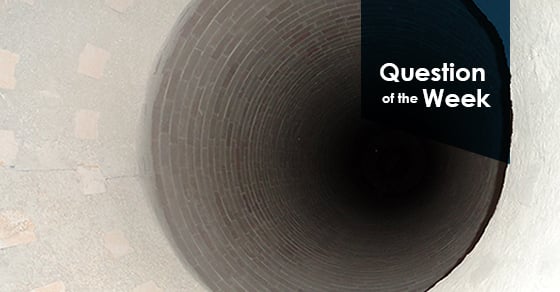

- Refractory. Direct heat can cause the kiln’s refractory to become tremendously dry, and thus, cracks may result. Inspecting the kiln for cracks and repairing them immediately is essential to preventing further damage to the kiln, because if left untreated, refractory can fall off, exposing the shell to the high temperatures within.

- The Burner. The burner nozzle, cone, and sensors should be inspected for wear and/or damage.

- Seals. When the kiln is in operation, intense heat can sometimes cause the seals to curl away from the drum, leaving them in a deformed shape. A deformed seal is an ineffective seal, and can cause unwanted air leakage into the kiln, disrupting the reactions occurring within.

- Alignment. Wear or damage to the tire/wheel, pinion/girth, and thrust roller are all signs that the kiln is misaligned. The drum may also be misaligned if you hear extreme chatter or vibrations.

Prevention is key when it comes to maintaining a rotary kiln. Regularly inspect and service the refractory, burner, seals, and alignment to keep the kiln running efficiently, and to extend the life of the kiln itself.

For more information on rotary kiln inspection and maintenance, read our blog post Rotary Kiln: Damage Prevention.