Hammer mills are a type of size reduction equipment, used to break down oversized granular materials. Breaking down oversize material helps to reach ideal particle size distribution for feedstock.

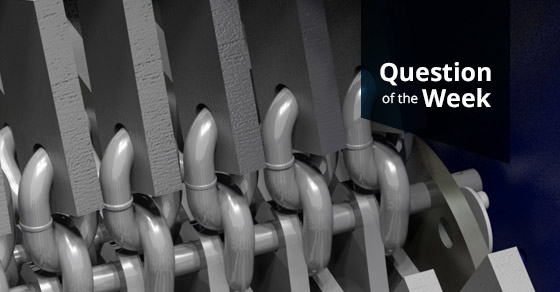

FEECO hammer mills use a central rotating shaft, with several ‘hammers’ attached to the pivots on the shaft. When the shaft turns, the hammers are swung via rotational energy, which causes them to collide with the material and break it into smaller particles.

Hammer mills are relatively flexible units, used in a variety of applications. They can break down both granules and pellets, and therefore, can be used in both pelletization and compaction granulation operations. They are commonly seen after the screening step in both processes, allowing oversize product to be broken down and put back into the process as recycle.

For more information on hammer mills, read our blog post Hammer Mills: A Reliable Solution for Particle Size Reduction.