Whether you are using a rotary dryer, rotary kiln, or rotary cooler, there is one thing that all these instruments have in common: they all use methods of heat transfer to carry out their jobs. Heat transfer is how heat moves from one source to another. Understanding the types of heat transfer, and how they differ, is an important part in understanding how a rotary dryer, cooler, or kiln works. Knowing how heat transfer works can help in sizing a machine, and can also help to anticipate where heat will be lost in a system.

Even though we might not notice it, we think about heat transfer all the time – From cooking, to global warming – heat transfer is constantly at work around us. There are a couple basic rules to remember when thinking about heat transfer. First, heat ALWAYS transfers from a hotter object to a cooler one; the opposite of this is just not possible. Second, some materials can transfer heat better than others.

Materials are categorized into two basic groups, depending on their ability to transfer heat. Conductors are materials that transfer heat very well. Some of the best conductors are the non-ferous metals, such as copper and aluminum. Ferrous metals such as steel and stainless steel are also good conductors. The opposite of a conductor, is an insulator. Wood, rubber, ceramic, and brick, are all examples of insulators, or items that do not transfer heat well.

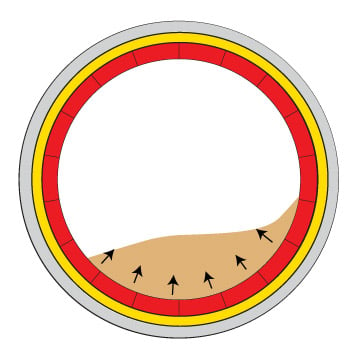

Conduction

There are three types of heat transfer: conduction, convection, and radiation. Conduction is the transfer of heat between two materials through direct contact. Think of touching your hand to the stove – this is a prime example of how conduction works. The heat of the burner, a physical object, is transferring heat to your hand, through means of touch. Other examples of conduction include curling irons, and cooking an egg on the sidewalk.

Conduction in a Rotary Dryer or Rotary Kilnis at work by transferring heat from the shell of the rotary drum, to the bed of material, via direct contact. |

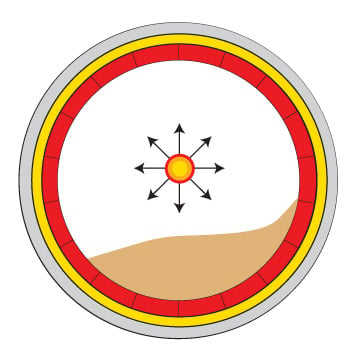

Convection

With convection, which is the primary mode of heat transfer for gases and liquids, heat transfers from a heat source, be it a liquid or gas, to a physical object. For example, a pizza cooks in the oven by means of convection: the heat from the oven is transferring from the heat source to the colder object, ie. the pizza. Convection works by the moving of the liquid or gas atoms in response to the heat. Once moving, the atoms can move around, in a sense, to surround an object, therefore heating it. Other examples of convection include hot air balloons, and boiling water.

Convection in a Rotary Dryer or Rotary Kilnis at work by transferring heat from the process gases to the bed of material. |

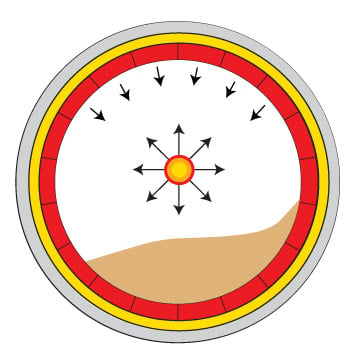

Radiation

The third type of heat is radiation. Radiation is the transfer of heat through a direct path.This is different from conduction and convection, because it does not require physical contact (conduction), and because it is a direct path, it cannot surround an object (convection). Radiation works similar to light. An easy way to understand radiation is by thinking of getting a tan. If you are sitting on a beach, the sun, in direct contact you’re your skin, will tan your skin. But if you put an umbrella over yourself, you are blocking the sun rays. The sun rays don’t go around the umbrella, like convection, they are just simply blocked. Other examples of radiation include the sun heating the planets, and a fireplace heating a house. However, because heat rises in a fireplace, most of the heat from conduction is lost through the chimney, leaving the primary mode of heat transfer to your house as radiation.

Radiation in a Rotary Dryer or Rotary Kilnis at work by transferring heat from the process gases to the bed of material, and additionally from the material to the atmosphere. |

All of these principles apply to the operation of rotary dryers, rotary coolers, and rotary kilns. Depending on the type of system in use, heat transfers to or from a material differently. In the case of a rotary dryer, the material is being heated directly by the gases, ie. convection. However, the material is also getting heat from the shell of the rotary dryer through means of conduction. In an indirect fired rotary kiln, conduction is the only source of heat transfer. The refractory is heated and transmits the heat from the refractory to the material by direct contact. Radiation is also present in all of these scenarios, because heat is being transferred through the atmosphere.

In the case of a rotary cooler, material is transferring heat from itself to the atmosphere (remember, heat can only transfer from a hotter object to a cooler one).

Heat transfer is an important component to consider in the operation of rotary dryers, rotary kilns, or rotary coolers. Knowing how heat transfer works can help in sizing a rotary drum, and being able to anticipate how heat will be lost throughout the system.

FEECO has been custom engineering rotary dryers, kilns, and coolers for over 60 years. For more information, see our thermal processing page, or contact us today!