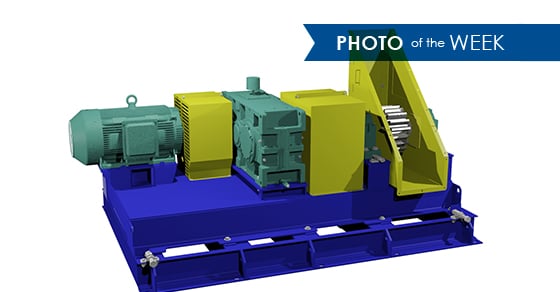

Today’s photo highlights FEECO’s unitized drive base in 3D.

The unitized drive base is mounting place for the rotary drum drive motor, reducer, and pinion gear. The drive is mounted on an adjustable one-piece base to allow for backlash adjustment of the pinion gear.

The base is bolted down to a solitary plate resting on leveled mounting pads. Eight screws are used to adjust the entire base, a major convenience which means not having to separately realign each component of the drive.

FEECO’s unitized drive base makes install, alignment, and maintenance of rotary drum drive components easier. Additional benefits include:

Quicker Installation. The unitized drive base is shipped in one piece, and is pre-assembled and pre-aligned, allowing for quick installation.

Savings in Labor. Backlash adjustments without the unitized drive base often take two men, two or more days to accomplish. With the unitized drive base, adjustments can be checked in minimum time, saving manpower and money.

Increased Gear Life. FEECO’s unitized drive base can add life to the girth and pinion gear because it allows drum personnel to easily inspect, and correct, mis- alignments.

To learn more, visit our rotary drum webpage for an assortment of content, or contact FEECO today.