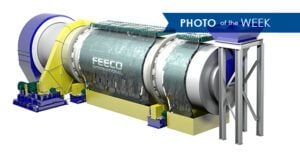

A Look at Indirect Coolers

Indirect rotary coolers are a special type of industrial cooler used to resolve unique cooling application challenges. Although not as commonly used as a direct rotary cooler, the use of an indirect cooler is an essential tool for cooling bulk solids in specialized applications. How …