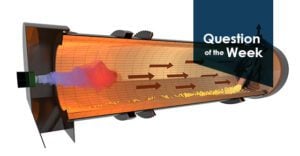

Why do Rotary Kilns Need Refractory?

Rotary kilns use high temperatures to cause a chemical reaction or physical change in a material. In most cases, these high temps would destroy an unprotected carbon steel shell, and for that reason, refractory is used. Direct-fired rotary kilns employ refractory; indirect-fired kilns do not. …