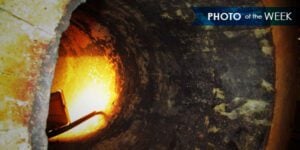

Photo of the Week: Rotary Kiln Refractory Build-up

This week’s photo shows the interior of a rotary kiln, as a technician works to remove build-up on the refractory. Build-up can sometimes occur in an over-temperature condition which causes product to melt and become sticky. A primary design requirement with all rotary kilns is …