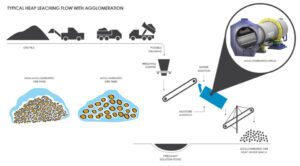

Photo of the Week: Ore Agglomerators

Our photo this week shows two ore agglomerators, used in the heap leaching process to extract metals such as gold, silver, nickel, or copper from ore. Once ore is mined and crushed, it is placed inside a rotary drum agglomerator, along with a leachate solution. …