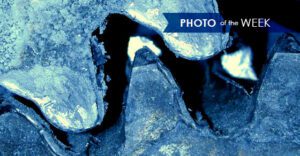

Photo of the Week: Worn Gear Mesh

Today’s photo shows the gear mesh of a gear and pinion drive, the mechanism that causes a rotary drum to rotate. The face of the teeth here are worn, an indication that the gear should be replaced, or they may break off. In most cases, replacement …