The Potash Drying Process: What You Need to Know

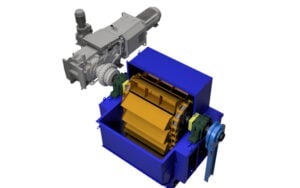

Drying potash is a vital aspect of processing the ore into a usable form for the fertilizer production process, as well as in finishing product coming off of the fertilizer production line. The following article highlights the basics of potash drying, including benefits, equipment, and …